Across the Loscam group, achieving best practice in health and safety is a core responsibility for every single one of us. Excelling in the provision of a completely accident-free operation will always be a number one priority for us as a group, and our talented, diligent, highly valued employees understand that their occupational health and safety is of the utmost importance to us. We are devoted in promoting a safety-first working culture. In 2019, many of our Loscam operation area achieved the goal of zero accidents through a series of occupational safety promotion activities.

Under the umbrella of our proud “Mission Zero” 2019 program, the Loscam team will continue to maintain a truly excellent safety record, including zero injury-caused deaths and little time lost to injuries. Moving forward together in Mission Zero, we will vigorously pursue our zero-injury targets with the implementation of leading safety practices to ensure we’ll be as free as possible from known and hidden dangers or hazards.

Cutting-edge training to keep us all safe

To ensure we comfortably comply with all relevant legal statutes and regulations, it’s Loscam’s policy to adopt the very best industry practices and international standards across health and safety… including the provision of cutting-edge training to all staff on machinery and tools, and accessible communication channels to raise issues and solve problems.

Productive collaboration at Loscam’s 1st “Group OPS & OHS Conference”

Ensuring a safe environment in every corner of our operation requires astute attention and close collaboration at all levels of the organisation, including productive communications between our higher level team members and managers across all our regions.

To enhance these communication channels, Loscam held our first “Group Operational Health & Safety Conference” in JiaXing, China, between 25th and 27th June, during which upper management and team members from all regions converged to discuss and contribute ideas in the name of best practice health and safety across the workplace.

Many achievements and innovations were shared, such as the Emerging Market team’s suite of solutions which significantly improve safety and boost productivity. For example, in an Indonesian depot upgrade this year, new lighting and ventilation systems drastically reduced the inhalation of harmful dust and chemicals.

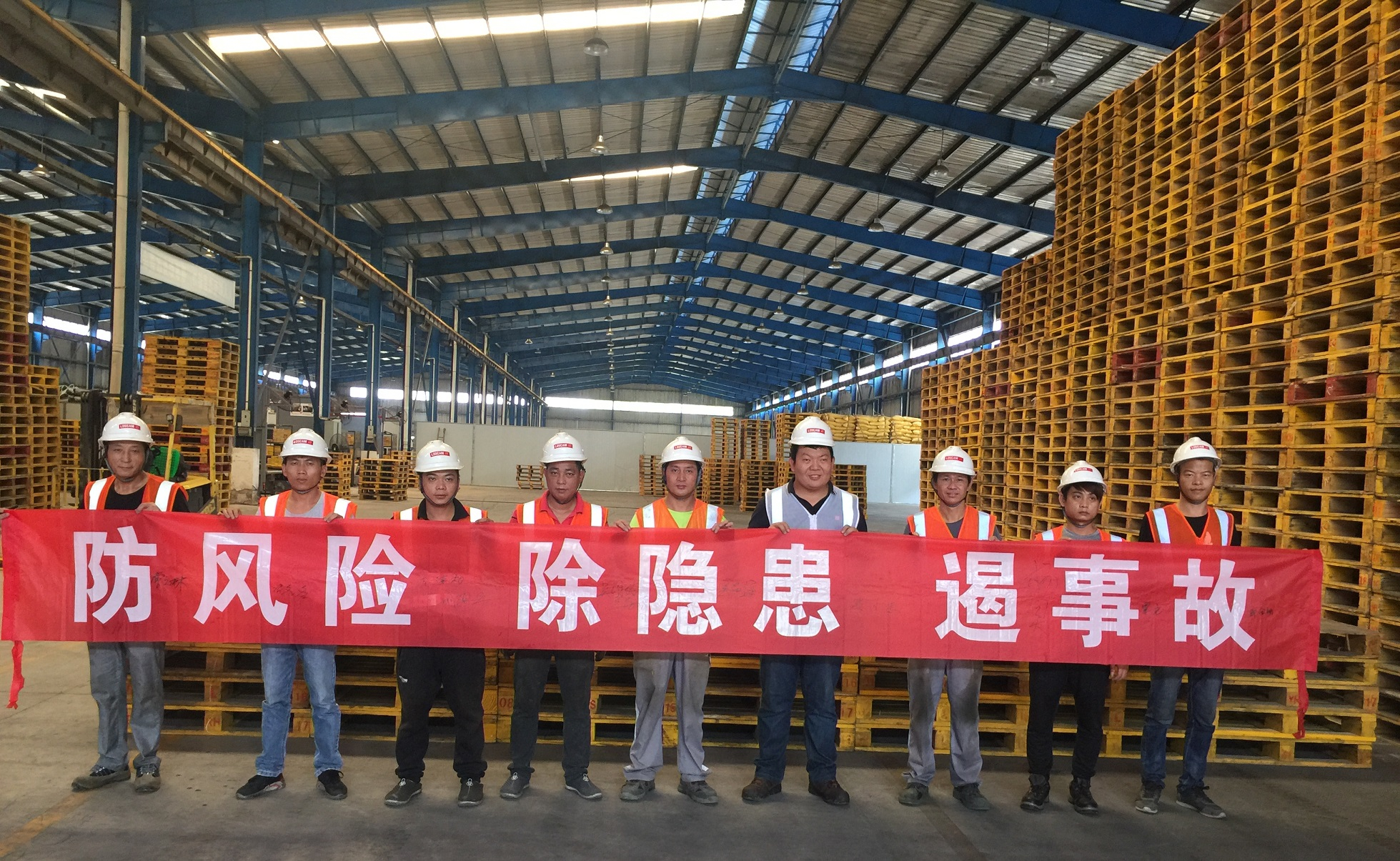

June sees a busy 18th “Safe Production Month” at Loscam China

June 2019 marked the 18th “Safe Production Month” for Loscam China. The theme of this year was “Preventing Risks, Eliminating Hidden Dangers, and Curbing Accidents.” Under the coordination by the company's safety committee, the depots and offices within the Greater China region carried out various activities such as safety presentations and training sessions, theme banners, online and offline safety consultations, safety knowledge contests, safety hazard investigations, fire and first-aid drills, and “safe shooting” photography, etc. Colleagues from the company showed much enthusiasm in participation. After the event, some colleagues expressed their feelings: “There is no second life, safety first. The safety of the operation site is never negligible.” It was a superb collaboration between our colleagues across all the activities, with one team member speaking for us all in remarking: “We only have one life and nothing is more important than safety. No stone should be left unturned in the name of safety, on every single Loscam site.”

Regions of SE Asia received award for their good practice of safety

Loscam Thailand receives the silver level of good practice in occupational safety and health management certificate and certificate of participation in the campaign project on driving of Inspection and development of the occupational safety, health and environment management system in high establishment and passed the evaluation criteria, this is presented by Ayutthaya Provincial Governor at the Ayothatya Municipality. Loscam Thailand will continue to maintain OHS development for protecting our people along with supporting the business achieve the target of injury free.

New products, enhanced productivity & superior safety in South Australia

Earlier this year, the Loscam’s Wingfield repair facility in South Australia celebrated the completion of an external hardstand surface upgrade, which supports enhanced product segregation and the growth in Loscam’s new product offering - including IBC’s, fold down bins and display pallets.

Importantly, this exciting upgrade investment also facilitated numerous improvements in site safety, not to mention the creation of an additional loading bay which triggers faster vehicle turnaround times. “I’m really proud of the Operations team and their ambition for success in our ongoing improvements. This completes the first of numerous 2019 site initiatives currently underway in South Australia… these are very exciting, very safe times”, remarked James Russell, proud state manager for South Australia, Western Australia and the Northern Territory.